Wisconsin Chimney Safety Specialists

Work with a certified Wisconsin chimney sweep and fireplace repair specialists that complies with NFPA 211, IRC, and state amendments. Our service includes HEPA-contained cleaning, Level I/II inspections, draft and CO testing under worst-case depressurization, and photo/citation reports. We perform tuckpointing, crowns, waterproofing, liners, spark-arresting caps, and factory-built system compliance. We expertly install EPA-certified wood, pellet, and gas units with proper clearances, venting, and permits. Periodic care plans ensure optimal system performance-and read on to discover our methods.

Key Takeaways

- We provide professional NFPA 211-compliant chimney assessments, HEPA-contained maintenance, and qualified sweep services adapted to satisfy Wisconsin codes and routine maintenance requirements.

- Expert draft and efficiency evaluation with precise draft measurements, carbon monoxide testing under maximum depressurization scenarios, and ventilation flow optimization for safe, efficient burning.

- Our masonry repair services include, including tuckpointing, chimney crown reconstruction, flashing installation and fixes, and moisture protection solutions, all with professional documentation and assessments and custom mortar color matching.

- Professional installation of chimney liners, caps, and spark arrestors compliant with UL/NFPA standards, incorporating high-quality stainless complete-protection caps and certified factory-built parts.

- We specialize in fireplace and stove installations and conversions, complete with necessary documentation and comprehensive documentation packages featuring photo documentation, applicable code references, and authenticated venting and pressure test documentation.

Complete Chimney Cleaning and Safety Inspections

Regularly book complete chimney maintenance and a NFPA 211-compliant safety assessment to lower fire risk and ensure proper draft. You'll receive systematic creosote removal using specialized brushes and rotary rods suited to your flue dimensions and liner type. We track soot levels, glaze formation, and draft measurements, then clean out any flue obstructions, including nests or masonry debris, using HEPA-contained methods to prevent indoor contamination. We check cap, crown, and flashing joints without addressing structural rebuilds. Technical carbon monoxide testing validates appliance venting under worst-case depressurization. We examine connectors, thimble seals, and terminations for clearance-to-combustibles compliance. You'll obtain burning technique recommendations-fuel moisture targets, load configuration, and air control settings-to prevent creosote formation. Final documentation include photos, NFPA 211 checklists, and improvement suggestions.

Professional Masonry Services: Repairs, Tuckpointing, and Reconstruction

Tackle masonry issues and crown deterioration early to stop water infiltration and protect structural integrity. You'll prevent freeze-thaw damage, chimney movement, and carbon monoxide risk. We inspect masonry following NFPA 211 and local Wisconsin codes, recording movement issues, salt deposits, and mortar damage.

When restoring mortar, we precisely align the gradation, color, and strength of sand, then make precise depth cuts in joints and tuckpoint with compatible Type N or S mortar, shaping to create robust, weather-ready finishes. We swap out deteriorated or shifting brick with matching materials, ensuring full-bed, fully buttered bonds. If crowns are cracked, we strip back to solid masonry and pour a reinforced crown with proper pitch with appropriate expansion space around the flue.

After heat damage compromises the chimney, we coordinate chimney relining after securing the masonry work.

Essential Chimney Safety Components

You'll inspect chimney liners for appropriate specifications, components, and UL approval to improve draft, control heat, and meet NFPA 211 and manufacturer guidelines. You'll choose durable caps-preferably stainless or copper with spark screens and bird/ember screens-firmly attached to resist uplift and prevent moisture entry. You'll implement thorough waterproofing by sealing crowns, maintaining flashing, and using vapor-permeable masonry coatings to stop infiltration without capturing moisture.

Understanding Chimney Liner Benefits

Few home improvements offer as many safety and performance benefits as a well-installed chimney liner. The installation safeguards combustibles against high temperatures, controls corrosive elements, and establishes a compliant venting pathway. A correctly sized and insulated liner enhances draft stability, minimizes condensation, and reduces creosote buildup-essential factors for fire prevention and extended liner life. You'll also experience enhanced energy efficiency thanks to better temperature maintenance and more efficient burning.

A liner protects masonry from damaging condensation and freeze-thaw cycles, maintaining structural stability. It's crucial when upgrading heating systems, repairing deteriorated flue tiles, or adhering to NFPA 211 and manufacturer listings. Listed stainless steel liners withstand heat cycles and fire events more effectively than unlined systems. With proper installation and annual inspections, you'll enhance performance, reduce maintenance needs, and ensure clean indoor air.

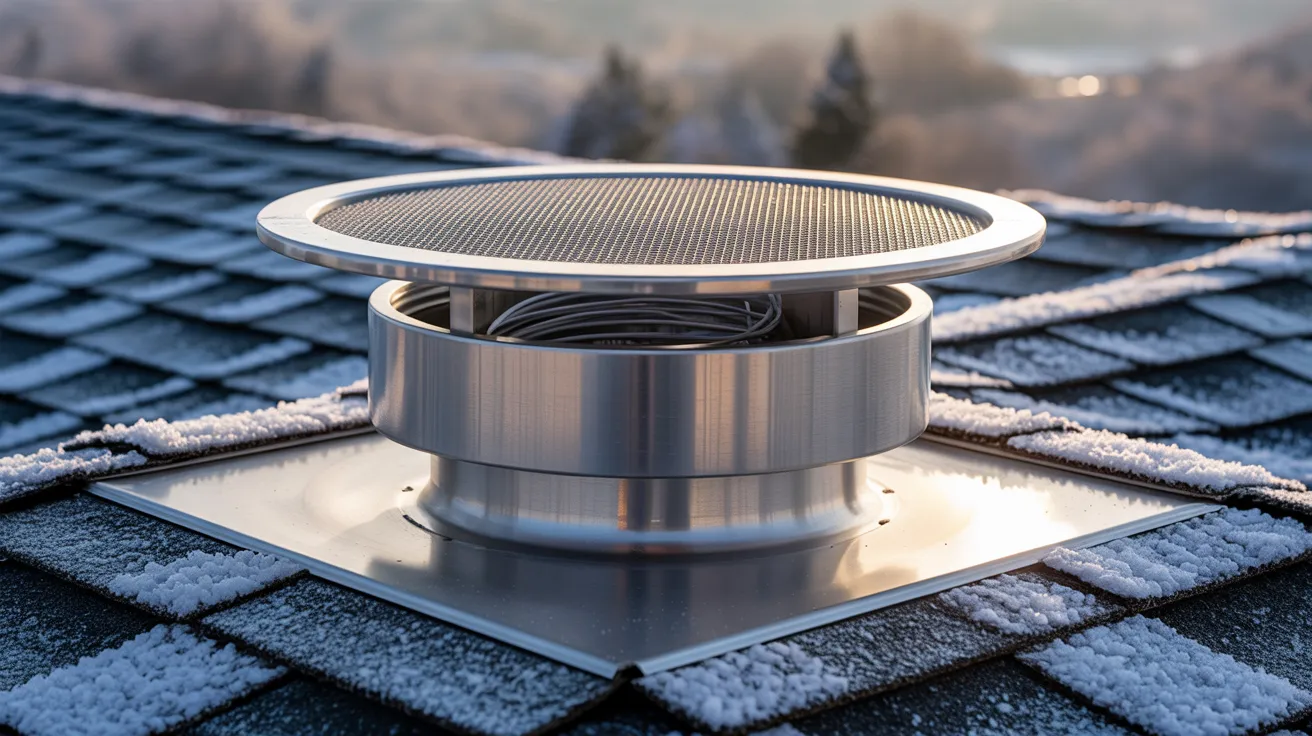

Picking Resilient Caps

After measuring and insulating the liner to maintain adequate ventilation and building code requirements, shield the top of the system with a durable, listed chimney cap. Choose stainless caps to prevent corrosion from Wisconsin freeze-thaw, acidic condensate, and creosote byproducts. Ensure UL listing, spark-arrestor features, and compatibility with your fuel type and liner termination. Specify a full-coverage cap that diverts precipitation, attaches to the flue or crown securely, and keeps required free area to eliminate draft restriction.

Install custom mesh measurements to balance spark containment and airflow: 3/4-inch for ember containment following standard requirements, bigger mesh only with manufacturer approval. Include bird and wildlife exclusion. Select removable screens to enable maintenance. Use stainless fasteners and sealed seams. Verify bonding/grounding if required by code or lightning concerns.

Key Waterproofing Strategies

From the crown to the firebox, proper waterproofing starts with a waterproof barrier preventing moisture and water vapor penetration while ensuring code-compliant airflow. You start by verifying the chimney liner is intact, certified, and correctly dimensioned; reline damaged flues to comply with NFPA 211 standards and manufacturer guidelines. Install a comprehensive cap featuring mesh and a water collar to deflect rainwater without limiting ventilation.

Safeguard the crown with UV-resistant elastomeric sealants that cover cracks and accommodate freeze-thaw movement. For masonry, use breathable protective layers that resist bulk water yet permit vapor diffusion, stopping spalling and efflorescence. Flashing must be counter-flashed and sealed at stepped connections. Repair mortar joints with Type N or S, then tool tight. Conduct annual inspections and refresh protective layers according to manufacturer specifications.

Expert Installation and Upgrade Solutions for Fireplaces and Stoves

Improve your hearth with solutions that meet current codes, enhance efficiency, and prioritize safety. You'll get systems correctly dimensioned to your room load, with spacing, chimney height, and connector diameters established per NFPA 211 and Wisconsin Uniform Dwelling Code. We assess flammable materials, floor protection, and anchoring requirements, then install listed appliances in accordance with manufacturer guidelines.

Select EPA-certified wood, pellet, or gas appliances with sealed combustion. Our team incorporates stainless steel liners, insulated chimney thimbles, and balanced flue terminations. Ventilation upgrades include dedicated fresh air intake, make-up air solutions, and mechanical ventilation coordination to preserve proper pressure relationships. Electrical and gas runs are routed with isolation valves, condensate traps, and code-compliant GFCI/AFCI safeguards. For hearth aesthetics, we select fire-resistant surrounds, code-rated mantels, and custom panels that enhance performance while preserving safe clearances.

Addressing Efficiency, Draft, and Smoke Problems

After your appliance has been correctly sized and installed to specifications, performance depends largely on proper draft, efficient combustion, and balanced pressure. Our first step is to verify proper flue sizing, liner continuity, and termination height. Following that, we assess draft levels, exhaust temperature, and oxygen content for optimal performance. When smoke enters the room, we apply corrective measures: fixing thimble and cleanout leakage, correcting offset issues, and upgrading chimney insulation for better draft.

In indoor settings, we conduct airflow optimization. We test home pressure levels during fan operation, confirm adequate makeup air, and add a direct outdoor air kit if required. We adjust air damper alignment, weatherstripping, and door latch tension. Finally, we address moisture in fuel, ash layer depth, and baffle alignment to ensure consistent burning and minimize creosote formation.

Local Codes, Certifications, and Seasonal Maintenance Plans

Be sure to check that your chimney and venting systems adhere to current Wisconsin Fireplace Codes, including specifications for clearances, liner specs, and chimney height guidelines. Hire technicians carrying Certified Sweep credentials to guarantee inspections, cleanings, and repairs align with approved standards and proper procedures. We'll implement a yearly maintenance schedule that arranges code-compliant inspections prior to heating season and after-season inspections to detect wear, creosote, and safety issues early on.

Wisconsin Fireplace Requirements

Even though fireplace design is significant, Wisconsin building and safety codes are the top priority. You need to ensure flues are sized according to appliance specifications, observe required spacing from combustibles, and install proper noncombustible hearth extensions in compliance with NFPA 211 and Wisconsin Uniform Dwelling Code. Stone chimneys need lined flues, approved caps, and appropriately flashed terminations. Manufactured systems require approved elements and manufacturer-specified supports.

Prior to beginning, secure necessary local permits and plan according to permit processing times that differ between municipalities. Keep detailed records of Code compliance with specification documents, photo evidence, and signed pressure and venting tests. Gas log or insert installations need proper shutoff valves, proper ventilation confirmation, and carbon monoxide detectors as specified in SPS 321.42. Solid-fuel heating units require spark arrestors and easily accessible cleanout access. Plan regular preseason inspections, conduct necessary sweeping, and maintain detailed records to ensure smooth insurance, resale, and occupancy verifications.

Verified Sweep Solutions

Beyond just the visual aspects, a certified sweep program ties your fireplace upkeep to local code requirements, professional credentials, and a documented maintenance schedule. You get a certified chimney expert who follows NFPA 211, IRC, and Wisconsin amendments for each service. Their specialized sweep training covers combustion air, clearances to combustibles, venting geometry, and fuel-specific hazards, preventing missed problems.

We perform regular maintenance checks including: initial Level I system check, interim draft and carbon monoxide assessment, and post-season Level II inspection when necessary. We provide thorough photographic reports, building code citations, and a prioritized remediation plan. Our certified specialists carefully examine your chimney system like caps, liners, dampers, hearth extensions, and smoke chamber integrity; they perform draft analysis and CO safety checks at the installation point. These records facilitates regulatory permits, insurance documentation, and property disclosures, ensuring your system continues to be safe, efficient, and code-compliant throughout the year.

Questions and Answers

Do You Offer Emergency Chimney Services During Nights, Weekends, or Holidays?

Yes, we offer urgent chimney assistance outside normal business hours, including holidays. We provide round-the-clock service with emergency specialists qualified under NFPA 211 standards. We address chimney fires, smoke issues, structural problems, and carbon monoxide dangers. Rely on immediate assistance, remote diagnosis, and secure temporary solutions. We maintain detailed records, conduct repairs meeting all regulations or ensure system safety until comprehensive service can be completed. You'll get comprehensive safety recommendations and subsequent appointment scheduling.

Which Parts of Wisconsin Do You Cover, and Do You Charge Travel Fees?

We serve Milwaukee suburbs, Southern suburbs, Fox Valley, Door County, Northern lakes, and Western Wisconsin. Not sure if we service your area? We provide NFPA 211-compliant inspections statewide with thorough inspections and verified draft measurements. Travel fees apply for locations beyond a 25-mile radius from our hubs; these fees are zone-based, transparent, and eliminated with repair services following inspection. You'll benefit from optimized service routes, thorough access assessments, and full permit handling for code compliance.

Are Itemized Estimates and Payment Plans Available

You'll receive comprehensive estimates outlining every aspect from materials and labor to safety requirements and code compliance. Every line item references local regulations and NFPA 211 requirements for verification of scope and compliance. We provide flexible financing options including upfront deposits, milestone payments, and inspection reserves. We'll itemize separately change orders, permit fees, and venting clearances. Written approval is required for all work details before work commences to guarantee clear understanding and safety compliance.

Do Your On-Site Technicians Have Background Checks and Insurance?

Yes - all our technical staff undergo complete vetting and carry full insurance. We implement thorough background verification processes before onboarding and maintain ongoing verification. You get professionals covered by comprehensive insurance coverage and workers' compensation protection for on-site work. We maintain documentation of qualifications, record training progress, and comply with NFPA and local code requirements. You'll receive service reports, job-site hazard assessments, and proof of insurance on request, delivering secure, accountable, and standards-compliant work from start to finish.

Do You Work With Homeowners Insurance for Damage Claims?

Indeed. You get full insurance assistance and claim help from initial inspection through final repair. We record damage with compliant documentation, detailed images, and NFPA 211 references, then liaise with your adjuster to align scope, pricing, and safety requirements. You authorize all work authorizations. We schedule emergency mitigation, provide permitting support, and ensure chain-of-custody for materials. You receive transparent progress reports, compliant workmanship, and a final closeout package for your insurance provider's records.

Wrapping Up

You choose well-maintained flues, not hidden creosote; sturdy masonry, not here failing joints; properly fitted liners and caps, not water intrusion; professional installations, not guesswork; optimal drafts, not smoky rooms. You adhere to NFPA 211, IRC, and local codes. You schedule seasonal inspections, record findings, and address defects. You verify clearances, test draft, and validate CO safety. You secure your home, maintain efficiency, and meet inspection-safely, according to code, dependably-today, this season, every year.